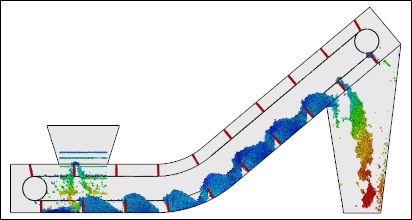

Each specific cluster (even different instances of the same cluster) can have a different size, and the user can designate the number clusters of that type per 10,000 clusters that will appear when the material is generated. Within a single material set, any cluster can be included any number of times. Each set has been optimized in shape and size to be computationally efficient thereby resulting in fast simulation times.Īlternatively, the user can manually create a material set by specifying which clusters to use. The user can easily select one of these sets from a drop down list. Newton also contains several built-in material sets. A material set can be automatically generated from the known size distribution. Various distribution curves are available (Rosin & Rammler for example). Once the fundamental cluster shapes have been created, the user can quickly and easily generate a size distribution curve based on the real material. AC-Tek’s Newton developers are continuously utilizing customer feedback to guide the addition of new cluster and material set features. An unlimited number of cluster shapes can be created, and then scaled up or down to meet the desired material size distribution curves.įurthermore, cluster sets may be imported and exported to and from either a CAD file or an Excel spreadsheet, allowing the user maximum flexibility. Newton allows for any size and number of spherical particles.įar more powerful however, is Newton’s ability to group multiple spheres of various sizes together to form an irregular particle, called a “cluster.” Clusters may be generated using the built in generation tool, shown in the image at right, or by manually specifying the size and location of each sphere in the cluster. Spheres are used because they are very computationally efficient. The first step in DEM modeling is the creation of individual particles and groups of particles.

Additionally, we have published several papers in this field, and have been involved with many projects using the DEM method. Our engineers and software developers have devoted an enormous amount of effort into developing the “Newton” DEM simulation software.

#Rocky dem simulation software free download full#

The DEM method has also been recognized in the manufacturing and pharmaceutical industries.Ĭlick to see our full page of Newton Examples.ĪC-Tek is a leader in this rapidly-advancing technology. The potential applications in the mining industry alone are huge, from conveyor belt transfer chutes, to apron feeders, to silos and augers. By correctly modeling the small scale individual properties of a system, its global behavior may be analyzed and improved. The total flexibility of the DEM method is one of its most tantalizing qualities. It must be combined with good engineering knowledge, design experience, and a firm understanding of the characteristics of the material being conveyed. However, the DEM method does not replace good engineering design and analysis it should be applied and used no differently than any of the other “tools” an engineer has in their toolbox. Advanced constitutive equations have now been implemented which allow accurate modeling of both cohesive and adhesive forces, allowing for the simulation of materials ranging from hard, dry lumps, to very sticky, and/or slimy material. With the tremendous advances in computing power over the past two decades, the DEM process is literally solved with a “brute force” approach. Essentially, the software repeatedly solves Isaac Newton’s equations of motion for each particle over very small time intervals.

In bulk solids handling, this involves the mathematical modeling of hundreds of thousands (often millions) of individual particles. The Discrete Element Method (DEM) is the name given to the solution process by which the macroscopic behavior of a system is determined by modeling its individual components. The proper modeling of granular flow using discontinuum mechanics is one of the most significant scientific advancements in the mining industry. It is developed and maintained by the engineering group at AC-Tek. Newton is extremely flexible and can handle a wide variety of material properties and geometries including conveyor transfer chutes, apron feeders, chain feeders, bucket elevators, and more. Material degradation, surface wear, impact damage, energy dissipation, and other fundamental parameters can easily be analyzed. A variety of constitutive models have been included to model a wide range of material properties including wet, sticky, cohesive material. Newton is a general purpose Discrete Element Method (DEM) simulation package used to quickly and accurately model three-dimensional behavior of granular flow.

0 kommentar(er)

0 kommentar(er)